The insulating properties of ceramics are well known and these properties have found application in advanced ceramic materials for substrates and packages.

Ceramic substrates and packages for electronic applications.

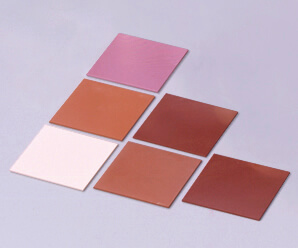

Substrates made from rubalit alumina ceramics.

At the same time the vacuum tight housings and substrates must.

Among the ceramics employed as electronic substrates and packages the dominant material is alumina aluminum oxide al.

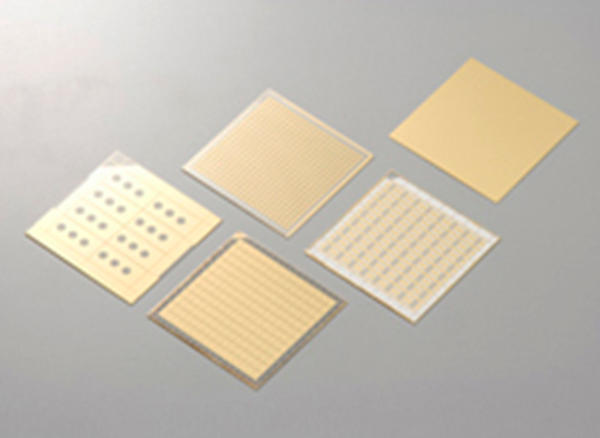

Direct bonded copper dbc substrates are commonly used in power modules because of their very good thermal conductivity they are composed of a ceramic tile commonly alumina with a sheet of copper bonded to one or both sides by a high temperature oxidation process the copper and substrate are heated to a carefully controlled temperature in an atmosphere of nitrogen containing about 30 ppm.

The outstanding surface quality on both sides makes it the perfect companion for any commercial thick film paste and even makes it suitable for a number of thin film applications sputtering.

Printed resistors and high current capacity trough conductive line structures are also available.

Htcc high temperature co fired ceramics alumina system and ltcc low temperature co fired ceramics glass ceramic system are available.

This ceramic material is characterized by its extremely high strength and thermal conductivity.

Rubalit 708 s with 96 al 2 o 3.

Kyocera ecu substrates provide high density circuit design high temperature durability good heat dissipation and high reliability with multilayer ceramics.

Over 150 us companies produce or supply electronic ceramics.